Scholt Energy and VDL Groep deploy industrial salt bath for sustainable demand management in the electricity market

Article from Scholt Energy from January 13. 2021

https://www.scholt.nl/en/

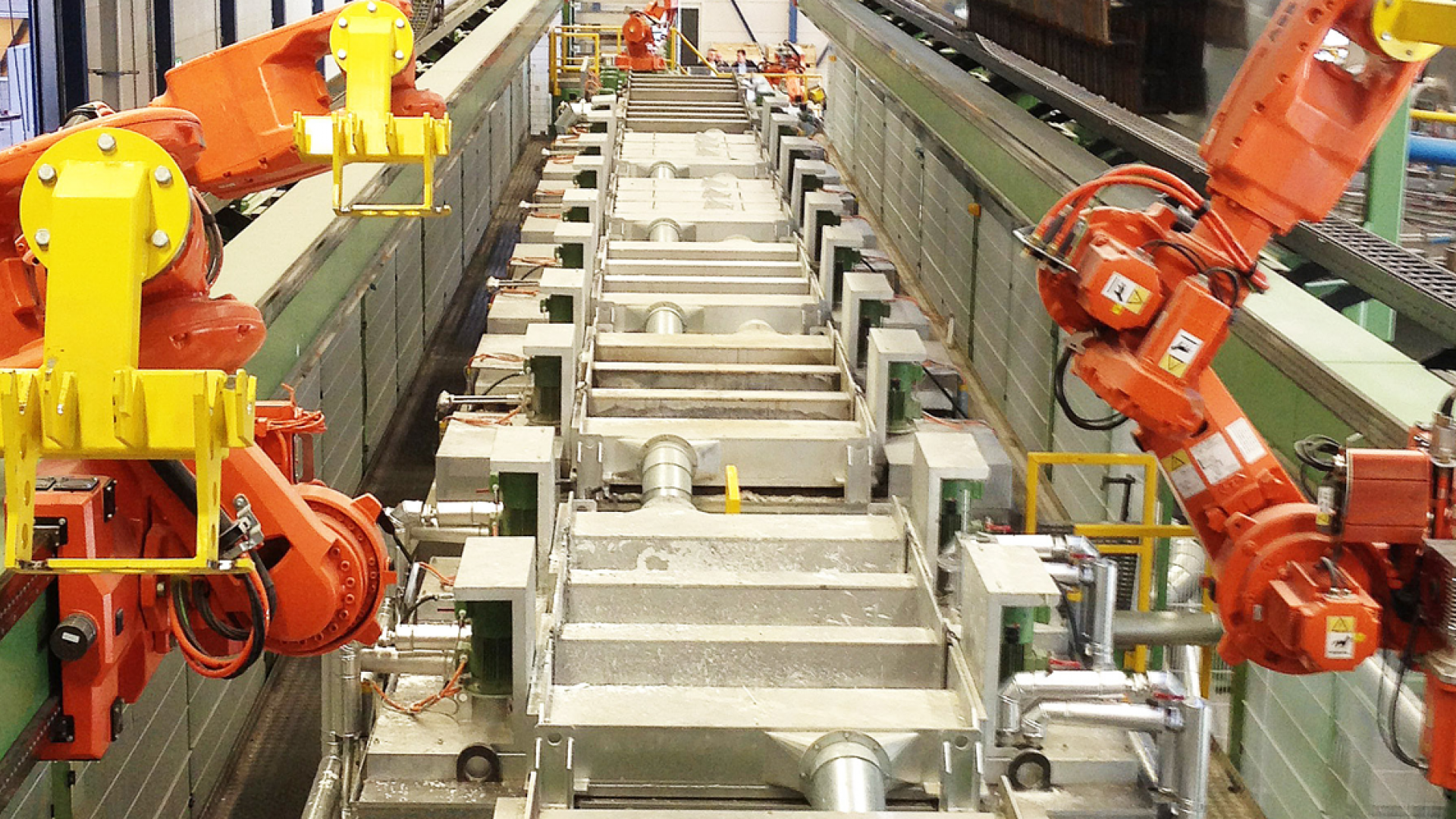

A large industrial salt bath that uses a lot of electricity for industrial metalworking. Not the first thing that comes to mind when thinking about sustainable energy transition. Yet industrial processes like these can play an important role in the rapidly changing energy market. Scholt Energy uses a thermal salt bath at VDL Weweler as emergency power for the Dutch electricity network. Recent research has shown that flexibly deployable industrial capacity can make a significant contribution to the Dutch energy supply at specific times.

With the growing supply of wind and solar energy in particular, the influence of weather conditions on the energy supply is increasing. This is making the energy market increasingly challenging. Because where does our energy come from when there's only a light wind or when the sun isn't shining?

Reducing CO2 emissions

Producing additional electricity in gas- and coal-fired power stations is still often the solution, but not a structural one because of the CO2 emissions that go with it. By 2030, all coal-fired power stations in the Netherlands must be closed down, which means that controllable capacity will disappear. Using previously stored electricity is also a solution. However, the capacity of storage systems is still far too small for this.

Part of the solution to this challenge lies precisely in the demand side of energy. After all, why should we produce additional electricity - resulting in more CO2 emissions - if we have the option of temporarily reducing demand? Demand management is an important part of the energy transition and will become even more important in the future. Scholt Energy already applies this demand management on an industrial scale at VDL, in a fully automated manner.

VDL Weweler, which produces components for the truck, trailer and commercial vehicle market in Apeldoorn, has a thermal salt bath for metalworking in its factory. The controllable power (energy demand) of this industrial process is comparable to that of about 1,000 households.

Demand management by Scholt Energy

Scholt Energy provides demand management for this process with its access to specific energy trading markets. The salt bath is linked by software to the emergency power market of the national grid operator in the Netherlands. Whenever supply and demand in the electricity network are in danger of becoming unbalanced, a control signal is sent. Scholt then ensures that the salt bath automatically consumes more (in the event of an oversupply) or less (in the event of a shortage) electricity. Scholt Energy's systems also monitor the available capacity and ultimately settle the cost.

No impact on business processes

Industrial processes are often characterised by continuity. This also applies to the salt bath, which must always remain within certain temperature ranges. Therefore, only the capacity that fits within these margins is used. In this way the process continuity is not endangered. At the same time, an extra revenue model is created without significant investments and a contribution is made to accelerating the energy transition. The new revenue model arises because the provision of emergency capacity is offset by the national grid manager.

Much broader potential

The application of demand-side management creates more scope for incorporating weather-dependent energy sources, such as sun and wind, into the energy network. In this way sustainability, but also security of supply and affordability can be improved. Industry therefore has the potential to make a major contribution to facilitating the energy transition. A solution like VDL's can be applied in many other places, including the steel, aluminium, paper and food industries. In the latter category, for example, the energy demand for large cooling and freezing installations can be controlled.

Source: https://www.scholt.nl/en/news/scholt-and-vdl-deploy-industrial-salt-bath-for-sustainable-demand-management/

![]()